Flexi Plate - 229 x 129

Pickup available at 290 Federal Highway

Usually ready in 2 hours

Product Details

Fits: UniFormation GKtwo

Our high-quality spring steel Flexi Plate is made with a rustproof chromium alloy, ensuring both durability and flexibility. The Flexi Plate is custom-etched on both sides to provide an exceptional grip for your first layer.

Explore more info on the Flexible Build System for Resin.

Printer Fits: UniFormation GKtwo

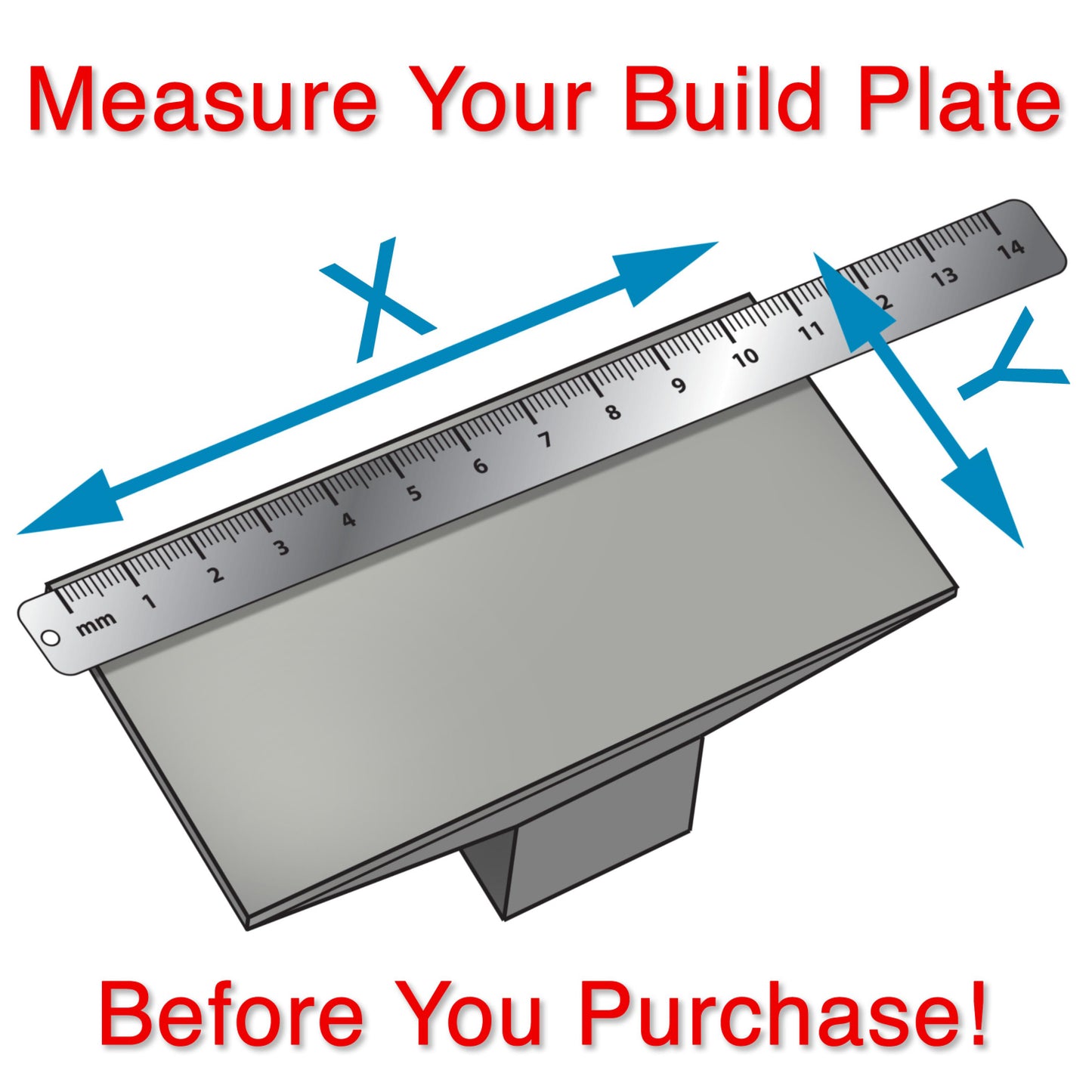

Do you have a printer similar to what's listed under Printer Fits or May Fit?

If you have a printer similar to the one described above and believe our solution could work for your printer, please follow our easy instructions on measuring your build plate. Let us know if your printer matches our specifications or is even close! We’d love to hear about it, and you might even receive a discount on Wham Bam® merchandise for your efforts. Click here for more info.

Includes:

1 Flexi Plate - 0.4mm spring steel

**Flexi Plate only, no Magnetic Base included**

Find the complete kit here.

Size: 229 x 129 mm

Would you like to upgrade to XTR?

Our eXTReme, extra thick 0.6mm Spring Steel Flexi Plate and 3mm composite Magnet Base resists peel forces of large prints, with a force of 800 gauss.It's available here

Video of Explanation FBSR vs XTR:

Sanding The Flexi Plate for more grip:

You can scuff one side of the Flexi Plate with 400 grit wet dry sandpaper (and clean well with IPA and the fresh paper towel a few times until the paper towel comes away clean) to get more grip.

Need Even More Grip? Try this tip:

If even more grip is needed use 320 or even 220 grit. Keep one side with our original etched surface and the other sanded, you can flip over as needed.

Resin Printing Best Practices with the Wham Bam Flexible Build System

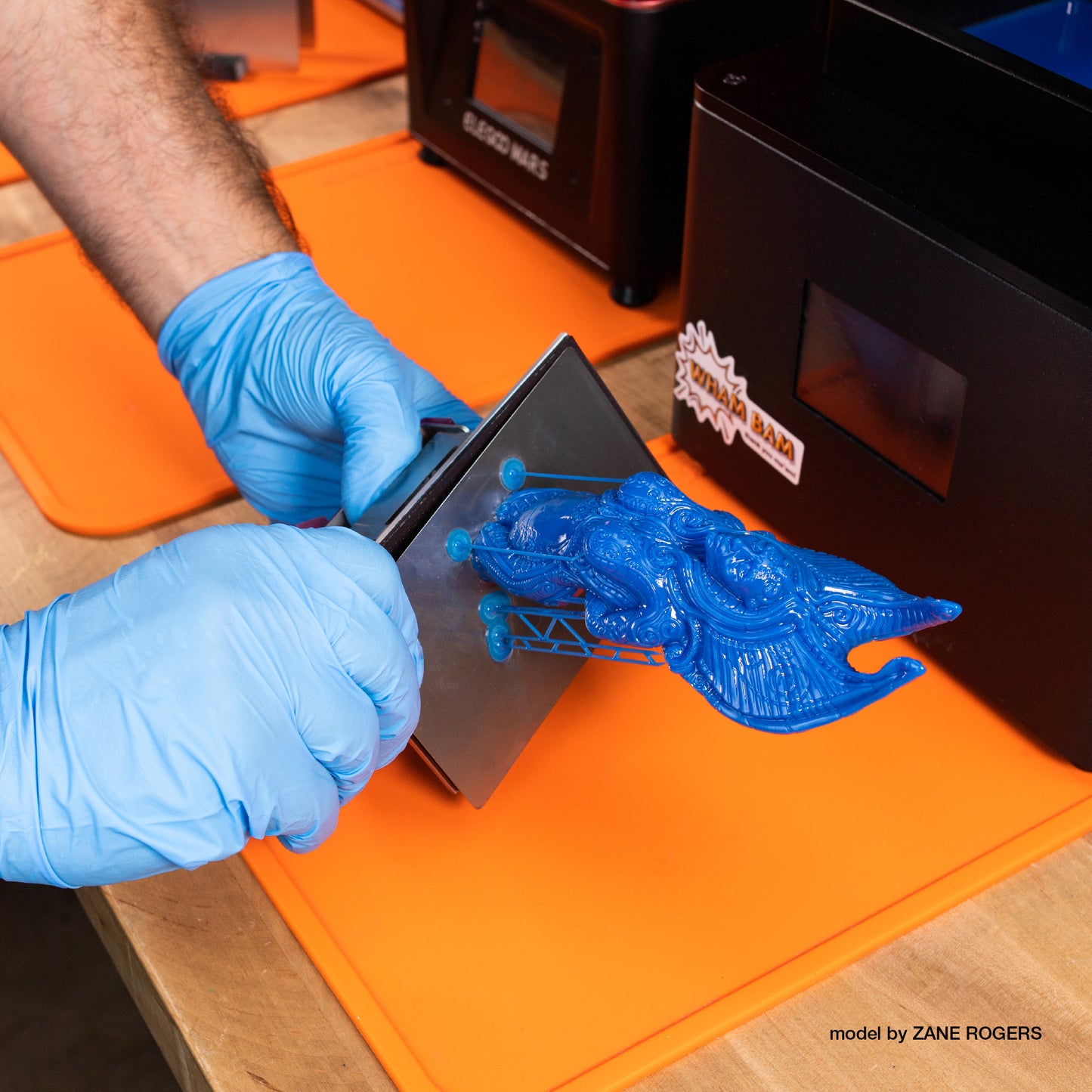

You can wash parts on the Flexi Plate

You can wash parts on the Flexi Plate or remove them from the Flexi Plate and wash parts separately.

Never cure on your Flexi Plate

Never cure parts on the plate to avoid depositing cured resin on the Flexi Plate.

Never leave resin between Flexi Plate and Magnetic Base

Do not leave your Flexi Plate on the Magnetic Base with resin between the two for longer than 2 hours.

Stuck Parts

Large rigid parts will pop off when you flex the Flexi Plate, but smaller supports may stick. For stubborn areas, carefully scrape with a spatula, chisel, or razor blade. If necessary, retouch the surface with 400-grit sandpaper.

Always clean your Flexi Plate & Magnetic Base between Prints

Always clean your Flexi Plate well with isopropyl alcohol and let it dry completely before placing it on the Magnetic Base.

Always Clean your Magnetic Base with isopropyl alcohol and let dry completely before replacing the Flexi Plate.