What Is The Flexible Build System?

Are you having a difficult time getting your 3D print to stick to your printer bed? Does your print peel up during a long print and destroy your work? Are you tired of temporary fixes such as glue sticks, hair spray, and painter’s tape? Once you get your print to stick, do you have to pry, chisel, cut the perimeter, or put your bed in the freezer, just to get your print off the surface without gouging the surface or cutting yourself?

We have created the specially formulated Wham Bam PEX Polymer Build Surface which surpasses PEI in temperature resistance, performance, and material ‘stickability”. It sticks so well you would have a heck of a time getting the print off the bed without our Wham Bam Flexi Build Plate. Simply remove the Wham Bam Flexi Build Plate from the Wham Bam Flexi Magnetic Base on your 3D printer when the print is finished and flex slightly to pop your print right off! See our demo video below.

Create Your Own Flexible Build System

Wham Bam is moving beyond pre-configured kits and putting control where it belongs—in your hands.

You can now build your own dream FDM Flexible Build System, selecting only the parts you need and saving money on every component in the kit.

_______________________________

Creating Your Kit

- Select one product from your printer’s size range

- On the product page, find the “Make Your Own Kit” section

- Add additional compatible parts from the same size range

- Automatically receive 10% off each added item

_______________________________

Have fun with this, mix and match, and create your ideal setup.

Some examples below:

- One Build Surface + Magnetic Base

- Two different Build Surfaces + Magnetic Base

- A pack of three Build Surfaces

- Any combination that fits your workflow

_______________________________

Build Surface Options

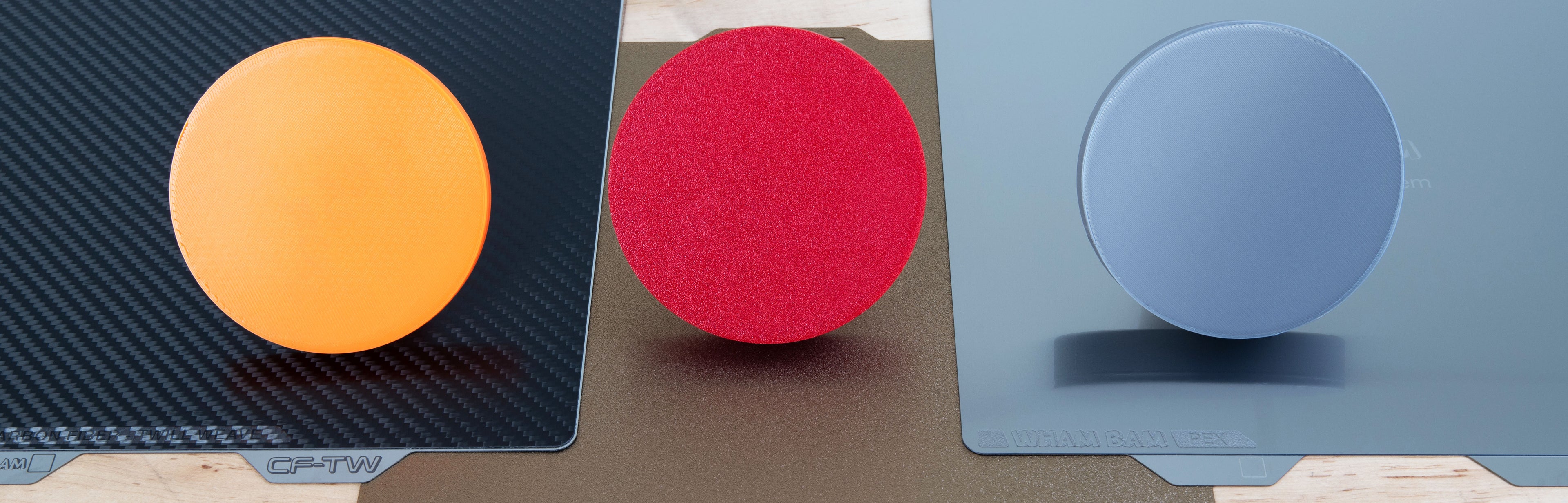

PEX / Powder-Painted ULTEM™ PEI / Authentic Carbon Fiber

_______________________________

Flexible Build System components are available in Regular and XTR versions (on select products).

Important: If your printer does not already have a magnet installed, or you would like an upgrade, be sure to include a Magnetic Base in your kit.

Flexible Build System for FDM

Detailed Surface Comparison

| Smooth PEX | Textured ULTEM PEI | Authentic Carbon Fiber | |

|---|---|---|---|

| Bottom of Print Finish | Smooth semi‑gloss | Strong texture | Smooth, slight CF weave pattern |

| First Layer Grip | |||

| Resists Damage | |||

| Ease of Release Once Cool | |||

| Release of Thin Layers and Brims | |||

| Best For | Smooth prints | High grip prints | Advanced materials |

| Use Care With | PETG, ASA | PETG, TPU | PLA |

| Attention Points | Remove parts when cool | Thin brims may bond | Care >270°C |

| Print Sides | One | Two | One |

| Prep | Scuff | IPA wipe | IPA wipe |

Select Your Printer Below:

A (Including AnkerMake & Anycubic)

C (Including Creality)

- Creality K2 Plus - Pre-order Flexi Plate with PEX and Flexi Plate with ULTEM PEI

Flexi Plate with PEX

E (Including Elegoo)

F - L (Including Flashforge & Lulzbot)

N - T (Including Prusa & Raise3D)

U (Including UltiMaker)

More solutions available

Click below to learn more options if you do not see your machine in the above lists!