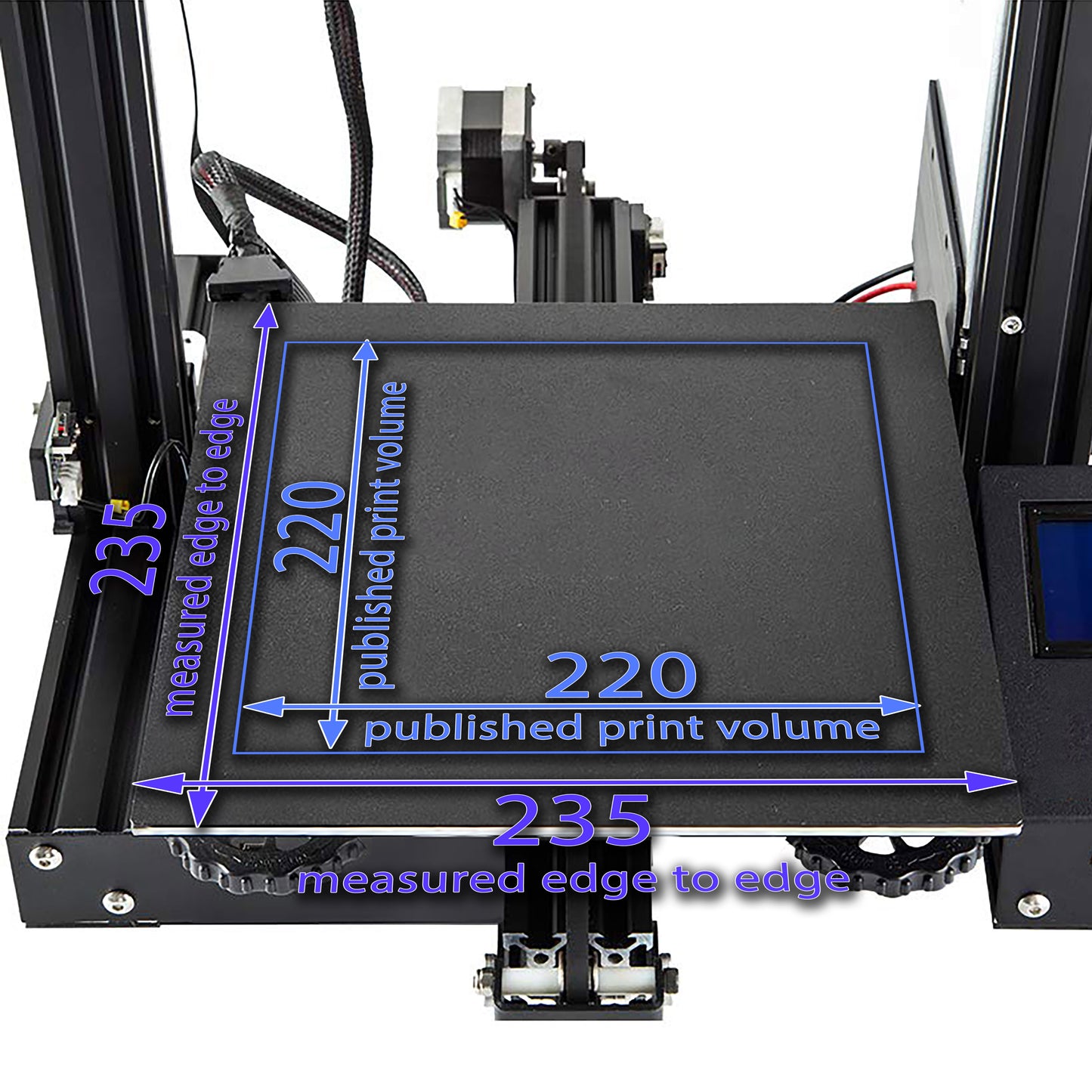

Flexi Plate with Carbon Fiber - Peopoly Magneto X - 476 x 339

Couldn't load pickup availability

Product Details

Fits: Peopoly Magneto X

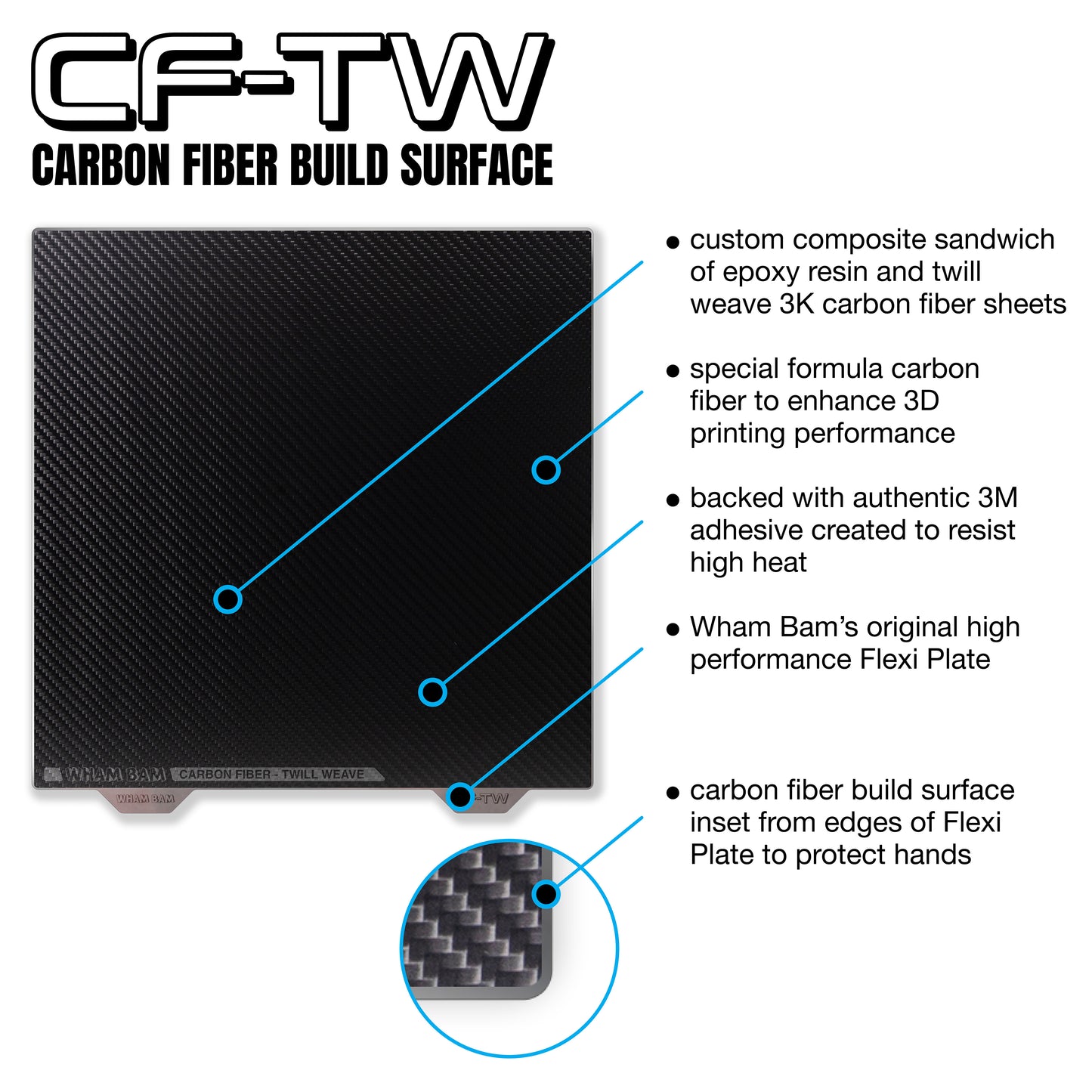

Our Carbon Fiber Build Surfaces are crafted from high-end, authentic carbon fiber composite panels, expertly bonded to our premium Flexi Plate using genuine high-temperature 3M adhesive. With proper care and use, this surface is built to last for many years.

The carbon fiber composite is meticulously engineered by layering woven 3k carbon material, which is then impregnated with epoxy resin. This 0.4mm thick packet is compressed in a high-precision mold within an autoclave, where vacuum and heat are applied to remove excess resin. The result is a lightweight yet incredibly robust surface, similar to those used in aerospace, automotive, and motorsport applications.

Our specially formulated carbon fiber composite offers significant advantages for 3D printing. Unlike traditional thermoplastic build surfaces like PEI, PEX, and PC, carbon fiber is a thermoset polymer, meaning it cures through a chemical reaction rather than heat and cannot be reformed by heat. This property ensures that the surface does not bond excessively with filaments, even those that require higher temperatures.

Virtually indestructible, our Carbon Fiber Build Surface can withstand the rigors of 3D printing without chipping or breaking. You can print almost any type of filament on it without damaging the surface. The only potential risks are a hot nozzle pressing directly onto the surface with force at temperatures above 150°C or printing thick layers at over 270°C.

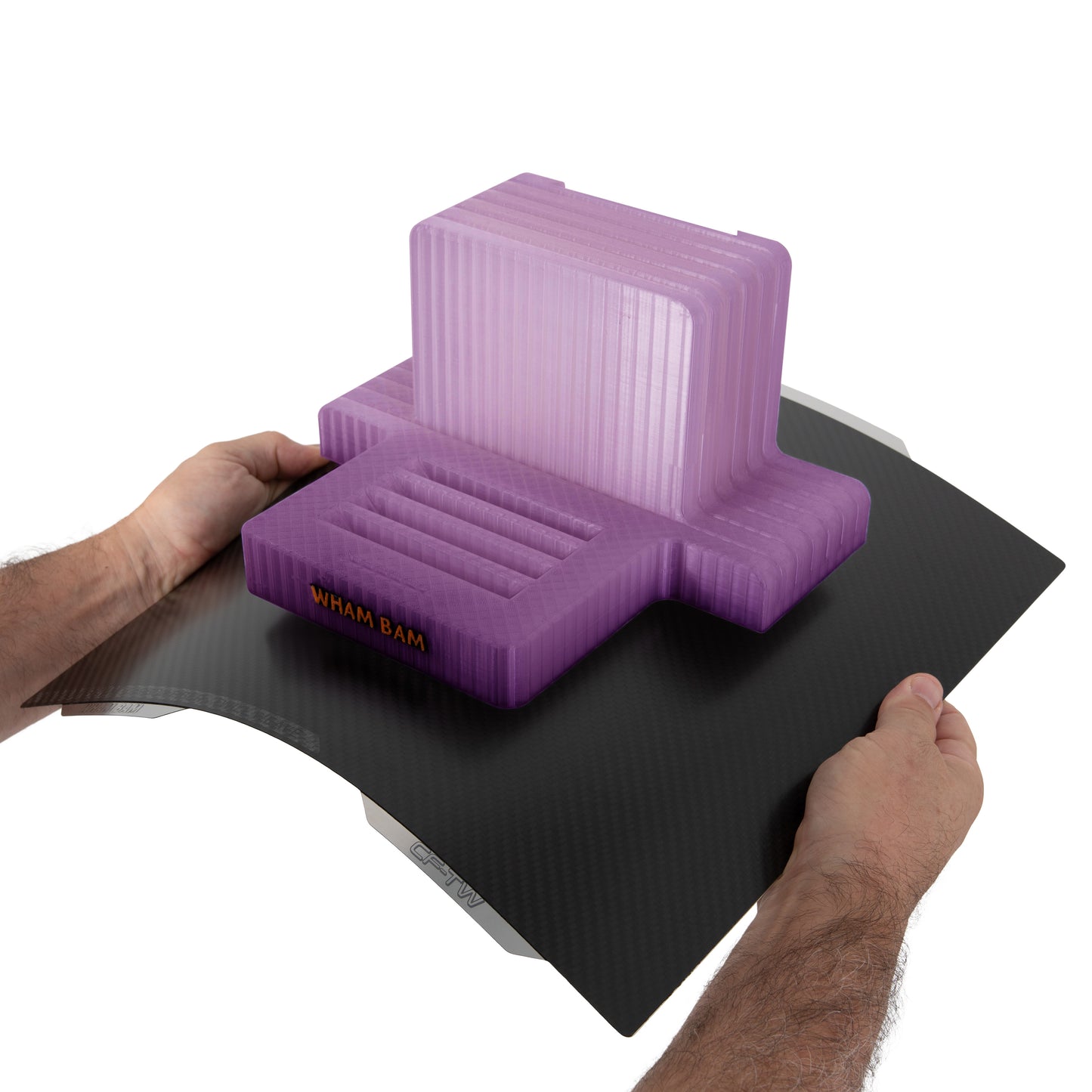

This build surface not only enhances the functionality of your 3D printer but also adds a professional touch. It’s easy to use with minimal preparation, attracts most filaments without the need for adhesives, and for those that do require them, only minimal adhesive is needed. The best part? After cooling, your prints will often release on their own or require just a slight flex to remove.

We developed our authentic Carbon Fiber Build Surface for its incredible performance and durability. Please note, it does not leave a pronounced pattern effect like the imitation “carbon fiber' sheets. These imitation sheets have low melt points, so they are not recommended for most filaments and therefore are easily damaged and will have a short life, and were just made to get a certain look on the bottom face.

What surface finish should you expect? Our true Carbon Fiber leaves a very smooth surface with the slightest of pattern only when seen in the exact cross light.

• Peopoly Magneto X

Do you have a printer similar to what's listed under Printer Fits or May Fit?

If you have a printer similar to the one described above and believe our solution could work for your printer, please follow our easy instructions on measuring your build plate. Let us know if your printer matches our specifications or is even close! We’d love to hear about it, and you might even receive a discount on Wham Bam® merchandise for your efforts. Click here for more info.

Includes:

Flexi Plate (0.4 mm) with Carbon Fiber Build Surface (0.4 mm)

**Flexi Plate only, no Magnetic Base included**Size: 476 x 339 mm

Note: You should already have a Magnetic Base installed on your printer as this is needed to use a Flexi Plate. Level bed after install.

View PDF Installation instructions here.

- The only preparation needed is to wipe it down with isopropyl alcohol (IPA) at a concentration of 90% or higher. Use fresh paper towels for this step—avoid using microfiber rags, shop rags, or any fabric that's been used before.

- Alternatively, you can use strong dish soap and rinse thoroughly with water to remove any oils.

- Ensure the sheet is thoroughly cleaned before using and avoid touching the surface with your hands to prevent leaving fingerprints.

- It’s recommended to wipe down the sheet between prints to keep the build surface free from contaminants and to prevent residue buildup from previous prints.

- Bed Temperature:

- Bed Leveling:

- Hot End Temperature:

- Adhesives:

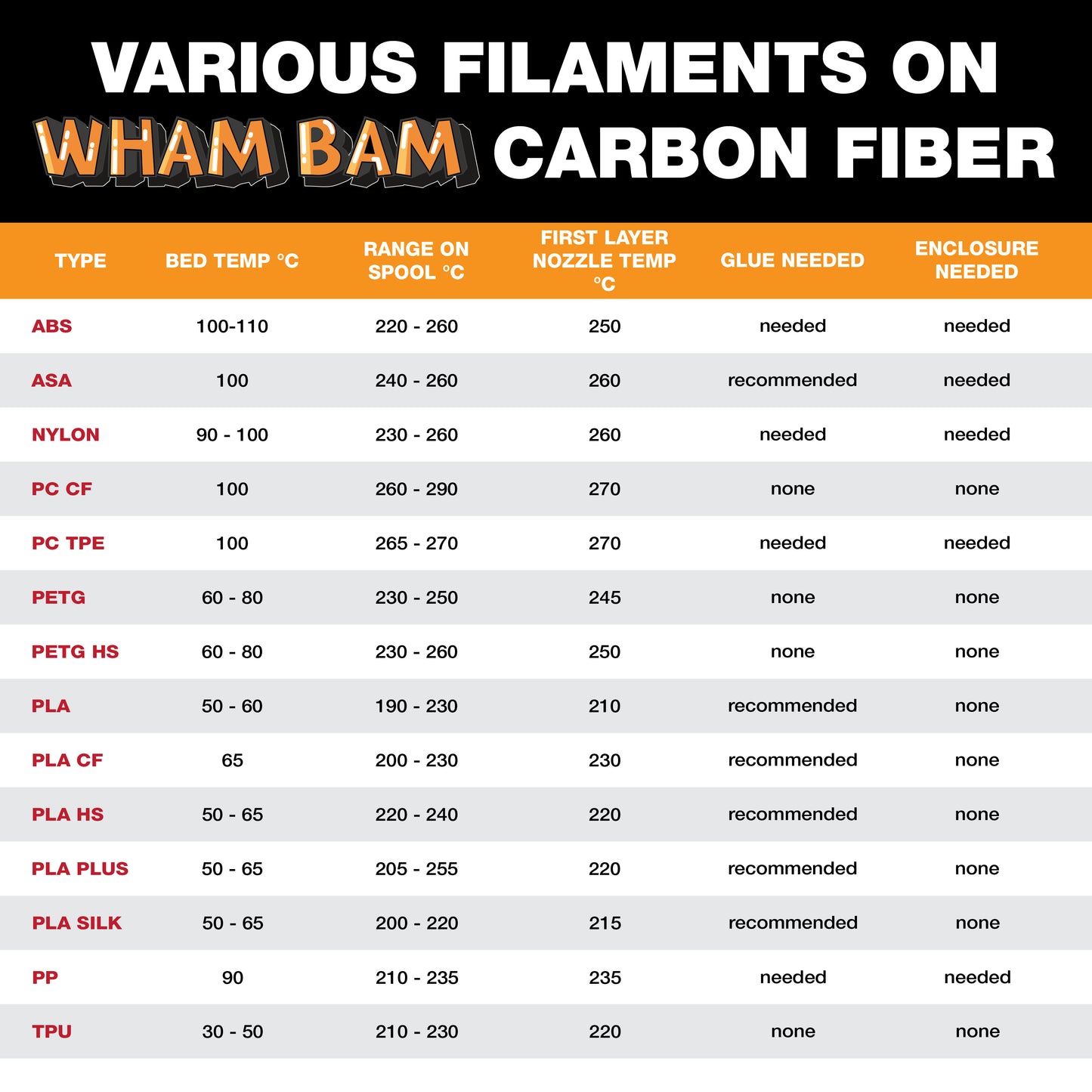

Heat the bed to the recommended temperature listed in our table, see product photos. A base temperature of 50-70°C works for most filaments that don’t require higher bed temperatures.

Carbon Fiber sheets may take longer to heat up than other build surfaces. This is especially noticeable on the Bambu machines which tend to send files to print before the surface is fully heated.

If you have an issue with adhesion you may want to consider preheating the bed to the desired temperature for about 5 minutes before starting the print. This can help resolve most adhesion issues. Some users found that adding a gcode script to the slicer start script helps to automate this.

Here is the gcode script which allows the machine to wait before sending the print, add this gcode to your start script in your slicer: G4 P600000 ; pause for 300,000 milliseconds.

It usually is placed after the M140 and M190 commands

For example:

M140 S[bed_temperature_initial_layer_single] ;set bed temp

M190 S[bed_temperature_initial_layer_single] ;wait for bed temp

G4 P600000 ; pause for 300,000 milliseconds

For printers with touch or tap bed leveling systems, set the nozzle temperature to no more than 140°C during leveling to avoid damaging the surface. While some systems tap lightly and work fine up to 170°C, others tap with more force and may leave marks at temperatures as low as 150°C.

It’s advisable to keep the hot end temperature for the first layer at or below 270°C to prevent damage to the surface.

If you notice any light distortions on the surface, they will likely dissipate if the bed is reheated to the same temperature and left for 15-30 minutes.

This build surface is meant to be used with adhesion promoters like: Vision Miner Nano Polymer, Glue Stick, or Magigoo for most filaments. Certain filaments like PETG and TPU usually do not need any other adhesives. We have found that certain filaments (like PLA and PC CF) and brands stick without adhesive and you can experiment to find your best settings and functionality.

If you’re using filaments prone to significant shrinkage, such as ABS and Nylon, it’s recommended to use an enclosure like the Wham Bam HotBox to maintain a controlled ambient temperature of around 40-50°C.

Please be aware that this is our only build plate designed for one-sided use. Carbon fiber is electrically conductive, and its woven fabric acts as a strong magnetic shield. If you try to flip the plate and use it upside down, the carbon fiber layer will interfere with the magnetic connection between the metal Flexi Plate and the magnetic base, resulting in poor hold.

A: We want to offer the highest quality and flatness possible by installing the proper industrial equipment. We recognize that during self installation one can impart a curvature between the two rigid panels and throw off the whole build surface tolerance.

A: Our true Carbon Fiber leaves a very smooth surface with the slightest of pattern only when seen in the exact cross light.

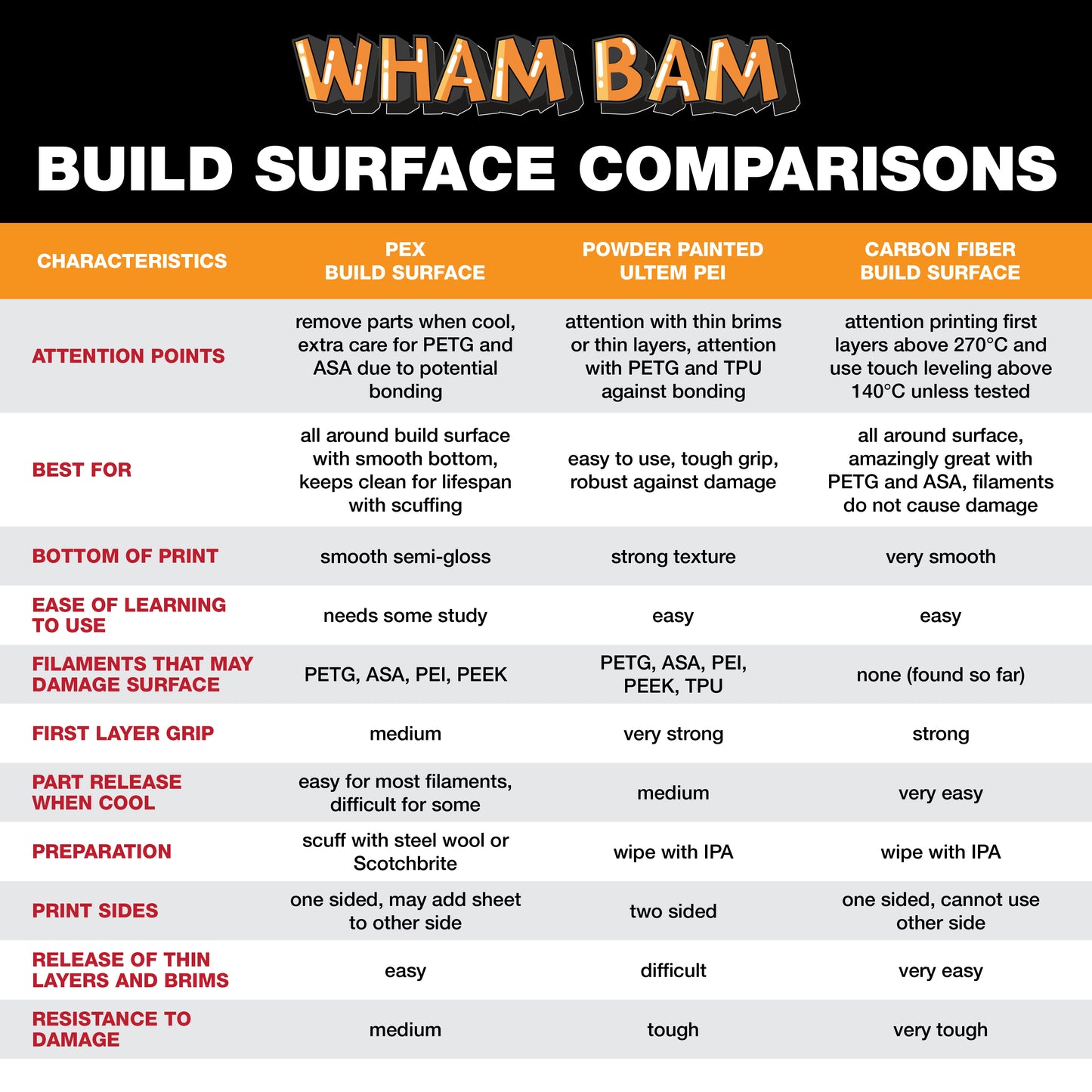

A: We are very proud of our PEX and Powder Painted PEI as well as our new Carbon Fiber Build Surfaces and find that each has its place in your lab!

Use our Powder Painted ULTEM PEI to have a great textured print surface. It is a very robust surface that is not easy to damage. Use our PEX for a wonderful smooth bottom finish and easy to print and release for most every filament. The PEX does require a bit more research and process to use well, and you must be careful when printing PETG, some ASA and other materials which may bond too well. The new Carbon Fiber Build Surface is our top of the line smooth build surface solution that is very robust and does not have issues bonding with certain filaments.

A: Yes! PETG, PEI, and PEEK all have similar molecular composition to PEI build surfaces and Wham Bam PEX and therefore tend to stick and bond and may cause damage. The polymer in the Carbon Fiber is a completely different family of plastic that does not bond with the above and other, so if you plan on printing PETG, PEI, PEEK, and even ASA you should get this build surface!

I have tried everything to try and get abs to stick and nothing worked. I sent multiple emails to support with no response. What a waist of $150. I have multiple carbon fiber plates from wham bam that work great. I think I got a bad one. Just sad that support did not respond.

Hi Firas,

We are sorry to hear you are having issues! We did reply to an email with a different question back in December but it could have wound up in your Junk folder if you did not recieve it. I had one of our techs reach out again! Try adding Technical@WhamBamSystems.com to your safe list or you can just give us a call at 954-391-8921 and talk to one of our technical support team to get this worked out.

Works perfectly on petg-cf ABS and PLA using nano polymer adhesive. I’m hesitant to try it on soft TPU may go back to the peopoly plate for that. Nicely made very happy with this product.

By far the best plate I've found for abs / asa prints.