Kit with PEX - LulzBot TAZ Series - 300 x 300

Couldn't load pickup availability

Product Details

Fits: LulzBot TAZ Series

(Please see full printer list below on the 'Fits & Contents' tab)

Upgrade your 3D printing setup with Wham Bam’s Flexible Build System, designed to enhance print quality and streamline your workflow. This system is a game-changer for anyone frustrated with stubborn prints that are difficult to remove. At its core is the Wham Bam PEX Build Surface, a specially engineered material that provides exceptional adhesion during printing and effortless release afterward. It’s paired with a flexible, magnetic spring steel Flexi Plate that snaps securely onto the provided Magnetic Base. When your print is done, simply remove the Flexi Plate and flex it slightly to release even the most intricate designs without damaging them.

The system is built to last, featuring rust-proof, spring steel that maintains its flexibility and strength over time, and powerful, temperature resistance magnets that ensure the build plate stays perfectly aligned during printing. It's compatible with a wide range of 3D printers, making it an ideal upgrade for hobbyists, prosumers, and industrial users alike who need a hassle-free solution to enhance their 3D printing experience.

Get everything you need in the Flexible Build System or upgrade to the Double Wham kit, which includes an additional Flexi Plate with PEX. This extra plate enables a continuous printing workflow by allowing you to start a new print on your 2nd plate while your first plate cools down.

Explore more info on the Flexible Build System.

Printer Fits:

• LulzBot TAZ 3

• LulzBot TAZ 4

• LulzBot TAZ 5

• LulzBot TAZ 6

• LulzBot TAZ Pro

• LulzBot TAZ Pro XT

• LulzBot TAZ Workhorse

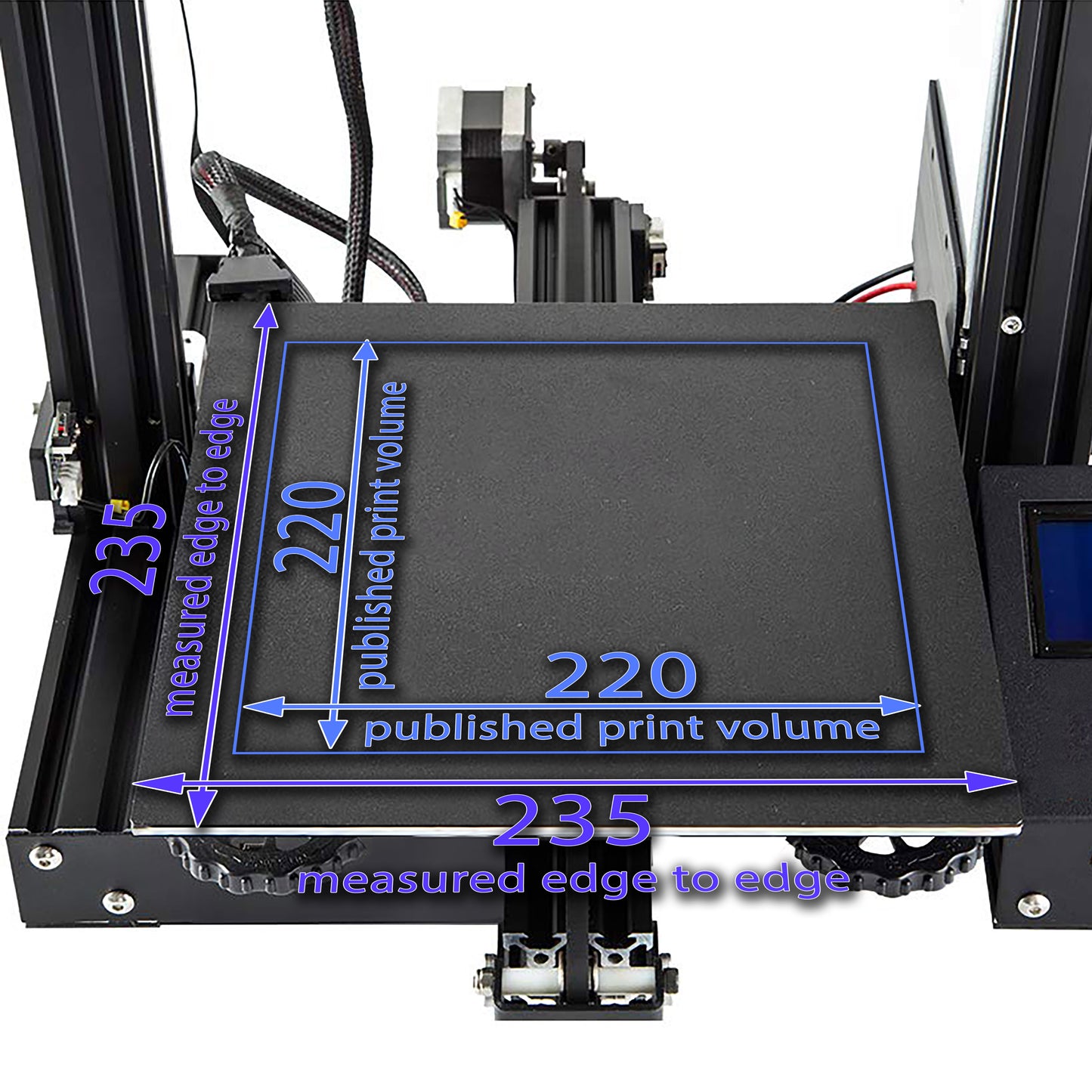

If you have a printer similar to the one described above and believe our solution could work for your printer, please follow our easy instructions on measuring your build plate. Let us know if your printer matches our specifications or is even close! We’d love to hear about it, and you might even receive a discount on Wham Bam® merchandise for your efforts. Click here for more info.

- 1 Magnetic Base

- 1 Flexi Plate with PEX Build Surface

- 1 Magnetic Base

- 2 Flexi Plate with PEX Build Surface

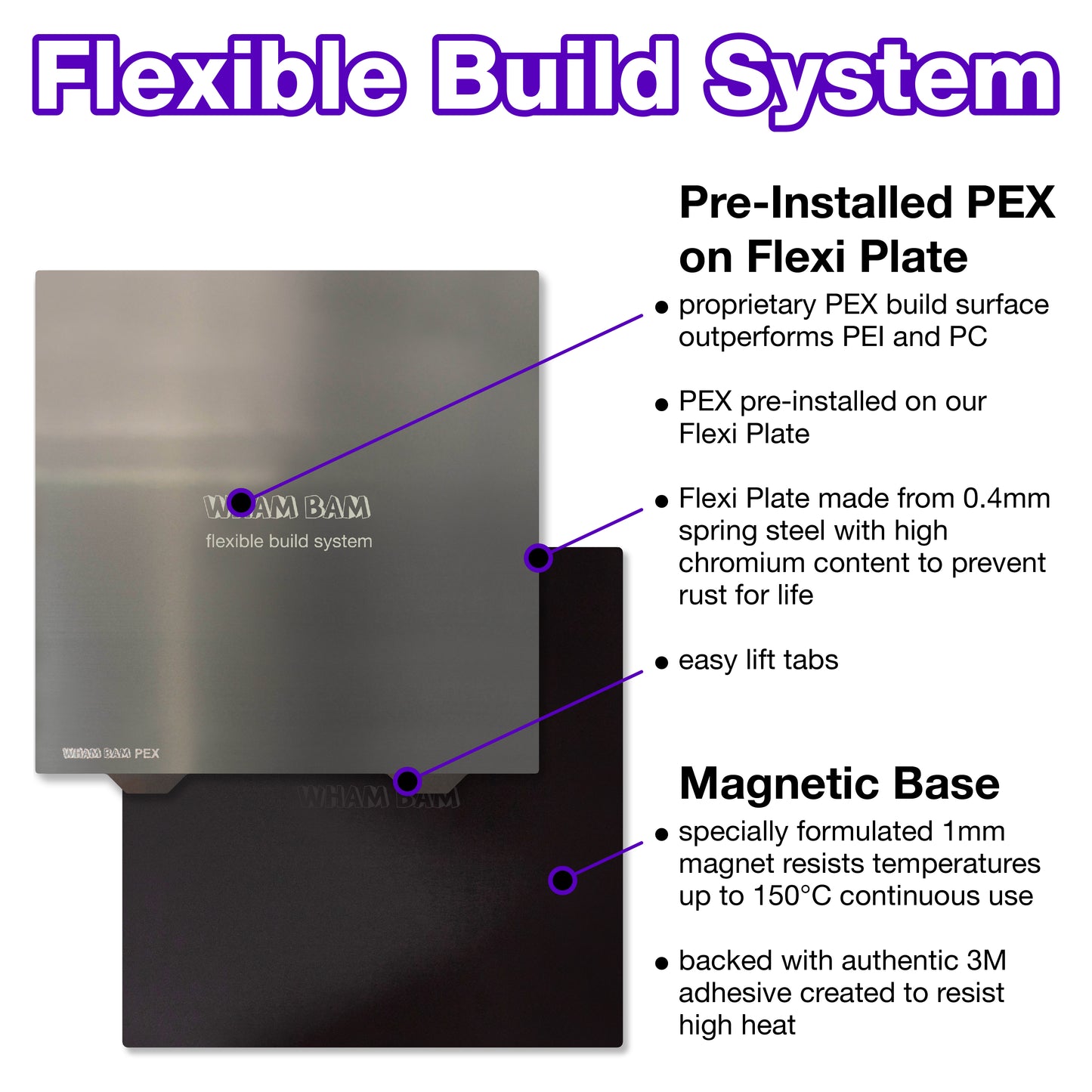

- 300 x 300 mm

- Magnetic Base 1 mm

- Flexi Plate 0.4 mm

- PEX Build Surface 0.35 mm

- Magnetic Base with 3M Glue rated to 150°C continual use

Please follow these steps when applying a new Magnetic Base:

- Remove old magnet (if any), and clean the bed well to remove any glue. Use isopropyl alcohol and a fresh paper towel.

- Use 220 grit sandpaper to rough up the metal surface uniformly and remove any excess contaminants. If your surface is painted, try to break through the paint layer with the sandpaper at least partially.

- Clean with 90% isopropyl alcohol and a fresh paper towel. Repeat with alcohol and a fresh paper towel a few times until the paper towel comes away clean. Do not use shop rags, wipes, etc., as these will propagate contaminants back to the surface. Use only fresh paper towels.

- Let the bed completely dry before applying the magnet.

- Let 3M cure for a full 72 hours before use.

Magnetic Base install video clip:

Make sure to rough up the PEX surface with 000 steel wool or red Composite Abrasive Pad (CAP is version 7447). On the first preparation, you will need to scuff in circles for 4-5 minutes until you have an even satin matte finish without seeing individual scratches with very little reflection. Clean repetitively with isopropyl alcohol >90% and a fresh/clean paper towel. Do not use other rags, microfiber, wipes, or towels, please see here.

If your machine has automatic bed leveling, run the leveling process and set your gap such that the first layer is well squished. For more details on achieving the right first layer squish, refer to this bed leveling guide.

If your printer uses manual leveling, follow the same guide for instructions on the leveling process.

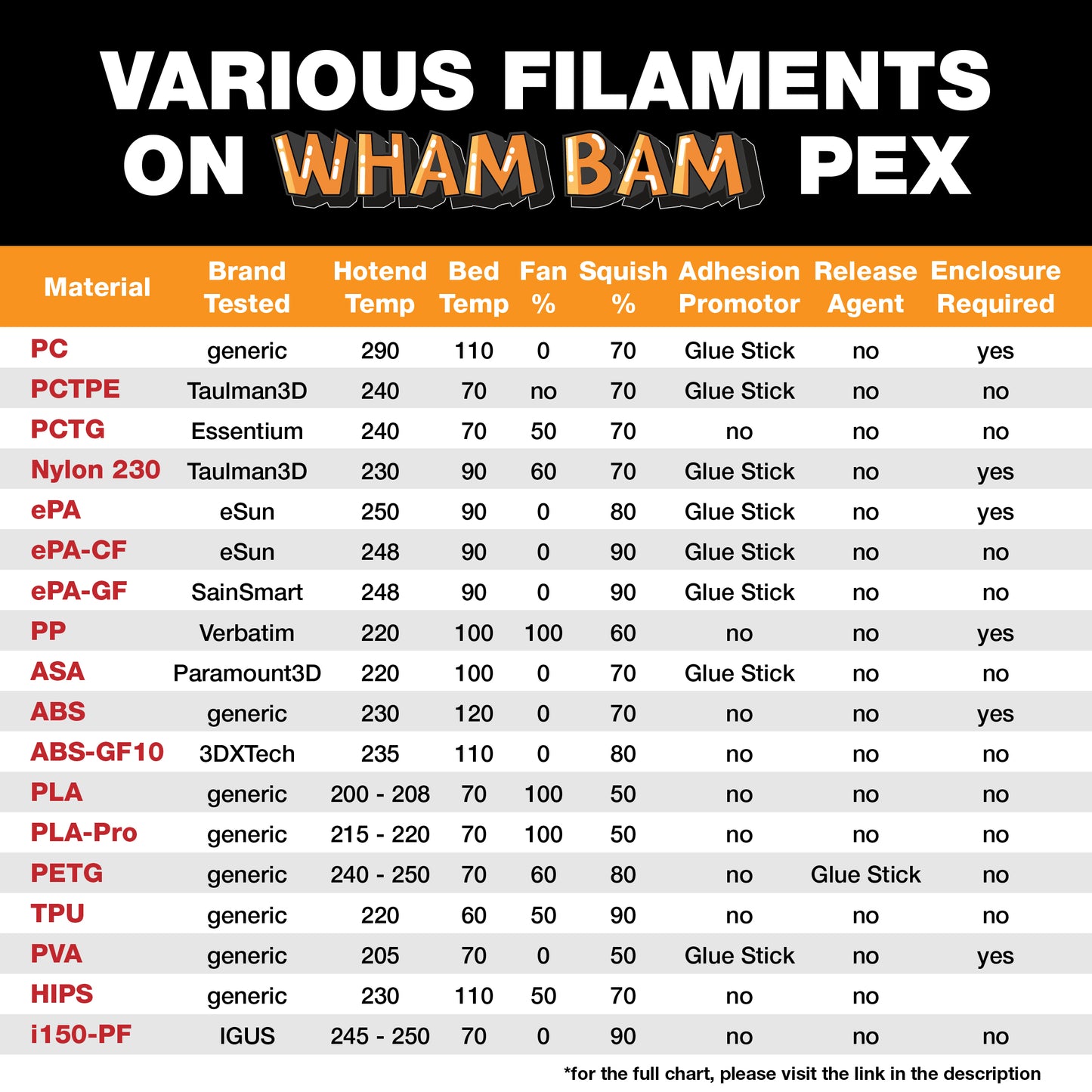

Always read your filament spool label

Your hot end temperatures should be set within the range printed on the side of the spool of filament. The first 3 layers should be toward the lower temperature range to avoid damaging the PEX. For example, if the hot-end range is 200-230° C, start with 215°C or lower and adjust as needed for your first layer. For bed temperatures, stick with the Wham Bam recommended temperatures as shown in the chart below.

When trying a new filament

We always suggest that when changing filament types and brands or adjusting settings, always print a small test cube (or our

Mini Whammy ) in the far corner of your build surface. If you do not get good adhesion, you may need to adjust your settings or use glue stick to promote adhesion. If it sticks for the full print and comes off easily once cooled, you are probably good to go when printing larger parts. If it bonds too well, adjust your settings, or use glue stick. When in doubt, use glue stick as a barrier layer. PETG and some other filaments, such as ASA, stick too well and typically need a barrier layer.

Printing PETG?

Learn more about problem-free PETG printing on our PEX

Full support info can be found on our support page.

Always read your filament spool label

Your hot end temperatures should be set within the range printed on the side of the spool of filament. The first 3 layers should be toward the lower temperature range to avoid damaging the PEX. For example, if the hot-end range is 200-230° C, start with 215°C or lower and adjust as needed for your first layer. For bed temperatures, stick with the Wham Bam recommended temperatures as shown in the chart below.

When trying a new filament

We always suggest that when changing filament types and brands or adjusting settings, always print a small test cube (or our

Mini Whammy ) in the far corner of your build surface. If you do not get good adhesion, you may need to adjust your settings or use glue stick to promote adhesion. If it sticks for the full print and comes off easily once cooled, you are probably good to go when printing larger parts. If it bonds too well, adjust your settings, or use glue stick. When in doubt, use glue stick as a barrier layer. PETG and some other filaments, such as ASA, stick too well and typically need a barrier layer.

Printing PETG?

Learn more about problem-free PETG printing on our PEX

After every print:

Always wait until the printed part and build plate are completely cool before flexing off and never flex when either is still warm. Never force off a print; always flex carefully once cool to remove the part.

After removing the parts always prepare the PEX for the next print by using either 000 steel wool, CAP pads, or a red Scotchbrite 7447 pad. Scuff for about 10 seconds, then clean with 70% or higher IPA and fresh paper. This will help to remove any traces of filament and prevent contaminant build up. Do not use rags, microfiber, wipes, or towels, please see here.

I am a Fan of the Wham Bam Flexible Build System.

1st Purchase was a Double Wham for my Elegoo Saturn 2 Resin Printer. This has been working flawlessly.

2nd Purchase was a Double Wham for my Taz 6 FDM Printer. Everything installed as expected. Was using the 1st Flexible Plate and was getting fantastic "glass looking" surfaces on PLA (various manufacturers) Prints... as well as with ColorFab nGen (nylon) filament. My wife then asked me to print something for outside use in the garden. For these prints I typically use a Taulman T-Glass filament for exterior use. Used all the typical settings for the T-Glass and when I went to remove the print from the Flexible Plate with PEX - the print popped off as expected - but the surface of the PEX was somewhat damaged. There are now indentations and marks within the PEX surface from this (1) singular print. When I started a new PLA Print, the marks within the PEX transferred to the 1st layer of the print. Very disappointing. So much for the Glass Finish that I was expecting.

I then pulled out the 2nd Flexible Plate (unused) that was part of the Double Wham purchase and there are multiple scratches within the PEX surface that will ultimately do the same thing... transfer to the 1st layer of the print. Again... Very Disappointing.

Note that using the supplied steel wool will Not remove these defects from either Flex Plate PEX surface. The Good - I like the Flex Plate addition to my FDM Printer. The Bad - I Don't like that a singular print on Flex Plate 1 rendered damaged... and Flex Plate 2 was actually scratched coming out of the original packaging.

Installed easily as documented, fits perfectly, works very well.